Laptop Repair for High-Density Components: Mastering BGA Reballing

BGA reballing is vital in laptop repair, but it’s complex due to small and delicate components. Proper techniques are essential for restoring performance. We’ll provide advanced techniques like precise alignment, cleaning, applying flux, and solder paste, and various soldering methods. By following our guidelines, technicians can reball BGA components in laptops with high accuracy and efficiency, making it a valuable addition to their repair skills.

1. Overview of BGA reballing process in laptop repair

Definition and purpose of reballing

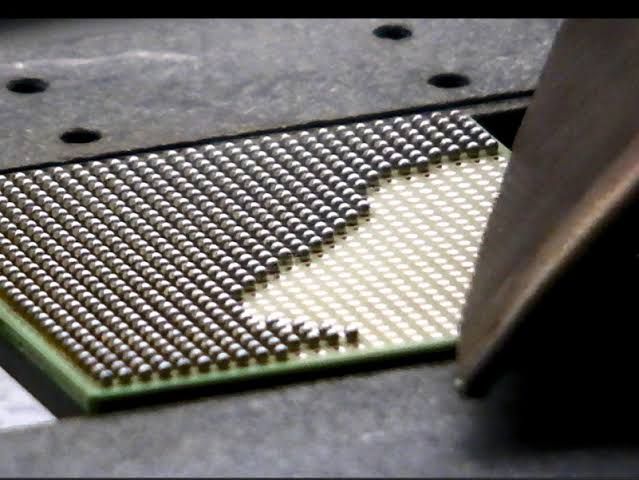

The image shows a close-up of a BGA reballing process being performed on a specialized workstation. Image credit: Solder.net

BGA reballing is a critical process in laptop repair that involves re-soldering high-density components on the motherboard. The purpose of reballing is to restore the performance of these components, which can suffer from issues like overheating or wear and tear. The BGA reballing process typically involves several steps, including cleaning, applying flux and solder paste, and soldering the components back onto the motherboard. To perform BGA reballing, technicians need specific tools and materials, such as a BGA rework station, soldering iron, flux, and solder paste.

To provide an overview of the BGA reballing process, we’ll start with a definition of reballing and its purpose in laptop repair. Then, we’ll list the tools and materials required for BGA reballing, as well as common issues and mistakes that can arise during the process. Next, we’ll provide a step-by-step explanation of the process, highlighting the critical stages and considerations. By the end of this section, you’ll have a solid understanding of the BGA reballing process, its importance in laptop repair, and the tools and techniques required to achieve successful results.

Pros and Cons of BGA reballing in laptop repair

The primary advantage of BGA reballing is that it can save you money by avoiding the need to replace an entire BGA component. Additionally, BGA reballing can be used to fix BGA components that have been damaged due to physical stress, overheating, or corrosion.

However, BGA reballing also has some disadvantages. The process can be time-consuming, requiring skilled technicians and specialized equipment. Additionally, there is a risk of damaging the BGA component during the reballing process. It is appropriate to consider BGA reballing when the cost of replacing the BGA component is high. It could be when the component is still functional but has suffered from minor damage or failure.

However, if the BGA component has suffered severe damage or failure, it may be more appropriate to replace the entire component.

Tools and materials required for BGA reballing

To perform BGA reballing in laptop repair, technicians need:

- BGA rework station (controls temperature, airflow, and heating profiles)

- Soldering iron (removes old solder)

- Hot air gun (reflows the solder balls)

- Tweezers (handles the BGA component and ensures accurate placement)

- Microscope (provides close-up inspection)

- Solder paste (adheres solder balls to the BGA component and motherboard)

- Flux (cleans the surface and improves wetting properties)

- Cleaning solvents (remove residual flux or debris)

- Wick or braid (cleans excess solder or debris)

Technicians should use high-quality tools and materials to achieve accurate and efficient BGA reballing in laptop repair. Each tool plays a critical role in the reballing process, and the quality and reliability of the tools and materials used can significantly affect the success of the process. By using the right tools and materials, technicians can achieve the best possible results in BGA reballing.

Technician using a BGA rework station to expertly repair high-density laptop components. Image credit: seamarkzm

Step-by-step explanation of the reballing process

After preparing the necessary tools and materials, the first step in the BGA reballing process is to clean the surface of the BGA component and the motherboard. This step involves removing any residual flux, debris, or oxidation that could affect the quality of the solder joint. Once the surfaces are clean, the technician can apply flux and solder paste to the BGA component’s pads and motherboard’s landing site.

The next step is to align the BGA component accurately on the motherboard. Precise alignment is critical to ensure that each solder ball on the BGA component’s surface connects to the corresponding pad on the motherboard. A slight misalignment can result in a faulty or incomplete solder joint, which can lead to issues like overheating or poor performance.

After aligning the BGA component, the technician can begin the soldering process. There are various soldering methods available, such as hot air and infrared soldering. The technician should select the appropriate method based on the specific requirements of the BGA component and the motherboard. During the soldering process, the technician should monitor the temperature and ensure that the heat is distributed evenly across the surface to prevent overheating or underheating.

Common issues and mistakes in BGA reballing

During the BGA reballing process, common issues can occur. It could be improper alignment, insufficient flux or solder paste, overheating, or underheating. To avoid these issues, technicians should use the right tools and follow best practices. They should apply the appropriate amount of flux and solder paste, ensure accurate alignment, and control the temperature.

By following these steps and techniques, technicians can successfully reball BGA components and restore the performance of high-density components in laptops. Proper BGA reballing can significantly extend the lifespan of laptops and ensure their smooth and efficient operation.

2. Advanced soldering techniques for BGA reballing in laptop repair

-

Importance of accurate placement and alignment

Accurate placement and alignment are crucial in BGA reballing in laptops. Technicians should use techniques for cleaning and preparing the BGA surface and pads, such as removing old solder and applying flux. Best practices for applying solder paste include using a stencil and dispensing the paste in small amounts.

-

Techniques for cleaning and preparing the BGA surface and pads

Soldering methods for BGA reballing include hot air and infrared. Technicians should select the appropriate method based on the specific requirements of the component and motherboard. Manual and automated methods are also available, with each having its advantages and disadvantages.

-

Best practices for applying flux and solder paste

To avoid heat damage and overheating, technicians should use the correct temperature and airflow settings, monitor the temperature during the soldering process, and avoid heating the same spot for too long. Troubleshooting techniques for post-reballing issues include checking for shorts, open circuits, and missing connections.

3. Soldering methods

Hot Air vs. Infrared; Manual vs. Automated

Two main soldering methods for BGA reballing in laptop repair are hot air and infrared. Hot air is a common method that uses a stream of heated air to melt the solder paste and reflow the solder balls. Infrared soldering uses infrared radiation to heat the solder paste and components, providing more precise and controlled heating.

Manual and automated methods are also available for BGA reballing, with each having its advantages and disadvantages. Manual methods require more skill and experience, as technicians must control the temperature, airflow, and placement of the BGA component manually. Automated methods, on the other hand, use machines to control the temperature, airflow, and placement, providing greater consistency and speed.

The choice of soldering method for BGA reballing depends on various factors, such as the size and complexity of the component, the type of motherboard, and the technician’s skill level. Each method has its strengths and weaknesses, and technicians should select the most appropriate method based on the specific requirements of the repair.

By using the right soldering method for BGA reballing, technicians can achieve accurate and efficient results, ensuring the proper functioning of high-density components in laptops. Hot air and infrared soldering, as well as manual and automated methods, all have their place in the BGA reballing process, and technicians should consider each method’s advantages and disadvantages when selecting the most appropriate method for their specific repair.

Tips for avoiding heat damage and overheating

To avoid heat damage and overheating during BGA reballing in laptop repair, technicians should use the correct temperature and airflow settings, monitor the temperature during the soldering process, and avoid heating the same spot for too long. Additionally, technicians should use the appropriate type and amount of flux and solder paste.

They should also use a preheating source, such as a preheating plate or an infrared lamp, to evenly distribute the heat and prevent warping of the motherboard. Another tip is to use thermal pads or thermal adhesive to protect sensitive components and prevent heat damage.

It’s essential to work in a well-ventilated area and wear protective gear, such as gloves and a mask, to avoid inhaling fumes or getting burned. Technicians should also ensure that the BGA component is securely held in place to prevent movement during the soldering process.

Troubleshooting techniques for post-reballing issues

Post-reballing issues can occur during BGA reballing in laptop repair, such as shorts, open circuits, or missing connections. Troubleshooting techniques include using a microscope to check for defects, using a multimeter to check for continuity, and performing a functionality test.

If shorts occur, technicians should isolate the shorted component and remove it. If open circuits occur, technicians should check for any broken connections and repair them using wire bonding or jumper wires. Missing connections can be caused by improper alignment or insufficient solder paste, and technicians should ensure accurate placement and adequate solder paste coverage.

Other post-reballing issues can include damaged components, unresponsive devices, or malfunctioning systems. In these cases, technicians should perform further diagnosis and repair as needed.

By using troubleshooting techniques for post-reballing issues, technicians can identify and fix any problems that may arise, ensuring the proper functioning of high-density components in laptops. Using a microscope and multimeter, isolating shorted components, repairing broken connections, and ensuring accurate placement and adequate solder paste coverage are all essential to achieving accurate and efficient BGA reballing.

4. Examples and case studies of BGA reballing in laptops

Real-world examples of successful BGA reballing in laptops

Firstly, laptop repair specialists have performed successful BGA reballing on Dell XPS 15. The graphics card issue was resolved, and the laptop functioned perfectly afterward. Secondly, a MacBook Pro faced a similar issue. Laptop repair experts successfully reballed the GPU, restoring the device to its full performance. Lastly, an HP Pavilion gaming laptop experienced video-related problems. Once again, BGA reballing resolved the issue, with users experiencing no further problems.

Challenges and solutions for specific laptop models and components

Regarding challenges, some laptop models have compact layouts. For instance, the ASUS ZenBook poses difficulties for laptop repair technicians. However, with precision tools and expertise, BGA reballing is still achievable. Additionally, some devices, like the Microsoft Surface, have components that are difficult to access. In these cases, laptop repair professionals often use specialized equipment to ensure a successful reballing process.

Customer testimonials and feedback on BGA reballing services

Finally, customers who have experienced laptop repair services for BGA reballing express their satisfaction. One user commented on the improved performance of their Dell Latitude. They appreciated the quick turnaround time and professional service. Another customer praised the BGA reballing service for their Acer Aspire, emphasizing the laptop’s restored functionality. Overall, customers and repair experts highly recommend BGA reballing services for laptop repair.

Conclusion

In summary, BGA reballing plays a crucial role in laptop repair. It resolves various issues, including graphics card problems and faulty connections. To ensure success, it’s essential to employ skilled technicians and use appropriate tools.

Key takeaways for successful BGA reballing include understanding specific laptop models, using specialized equipment, and following proven methods. By adhering to these recommendations, laptop repair services can achieve consistent results in BGA reballing.

For those in Singapore seeking laptop repair services, consider checking out VOLTA PC Upgrade & Repair (FKA Budget PC). They offer a wide range of laptop repair and upgrade services. With skilled technicians and excellent customer reviews, you can trust them for reliable laptop repair solutions. Visit their website today and give your laptop the care it deserves.